JN-85UT – Fully Automatic Strapping Machine

Major Features

- Easy tension adjustment and Power Saving Mode

- Solid Precise structure & rust free design suitable for marine environment

- Omron PLC system with forward & reverse timer available on request

- Optional-Auto Feeding & auto eject available on request

- Detection Function of feeding strap position

- Indication function of feeding strap position

- Re-feed strap position

- Newly designed motor prevents overheating

- Control voltage : 24 V DC

Option

- JN-85UTP with PLC Control

- JN-85UTR with PCB+Timer & Contactor Control

- MTC-85U (TR3)

JN-85UT – Fully Automatic Strapping Machine

JN-85UT – Fully Automatic Strapping Machine

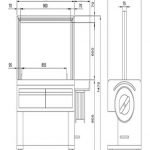

| Arch Size | 850 mm (W) x 600 mm / 400 mm (H) |

| Strap Speed | 25 cycles / minute |

| Tension Strength | 5 kg to 70 kg |

| Table Height | 810 mm |

| Strap width | 6 mm to 15 mm |

| Sealing Method | Heat Sealed |

| Package Size | 100 mm to 850 mm (W) & 60 mm to 600 mm (H) |

| Power Supply | 415 V 3 Phase |

| Dimensions | 1440 mm L x 645 mm W x 1534 mm H |

| Machine Weight | 240 kg |

| Driving Motor | 250 W ¼ HP |

JN-85UTP Fully Automatic Strapping Machine | Eagle Manufacturing Company

Discover the efficiency and reliability of the JN-85UTP Fully Automatic Strapping Machine, proudly manufactured by Eagle Manufacturing Company — a leading name in high-quality packing machinery. Designed to streamline your packaging operations, this Fully Automatic Strapping Machine is engineered to contain, unitize, protect, and secure your goods during manufacturing, warehousing, and shipping processes.

The JN-85UTP Fully Automatic Strapping Machine offers superior performance with its fast, precise, and consistent strapping capabilities. This advanced machine automates the entire strapping process, significantly reducing manual labor and increasing productivity. Ideal for a wide range of industries, it handles various package sizes and materials with ease.

Key features of the Fully Automatic Strapping Machine JN-85UTP include:

-

High-speed strapping for enhanced workflow efficiency

-

Adjustable tension control to protect delicate packages

-

Robust construction ensuring long-term durability and minimal maintenance

-

User-friendly interface for easy operation and quick setup

-

Versatile compatibility with multiple strapping materials

Eagle Manufacturing Company’s Fully Automatic Strapping Machine JN-85UTP is perfect for businesses looking to improve packaging speed and security while reducing labor costs. Whether you need to secure cartons, bundles, or pallets, this machine guarantees reliable strapping every time.

Invest in the JN-85UTP Fully Automatic Strapping Machine today to enhance your packaging line with Eagle Manufacturing Company’s trusted technology. Experience seamless operation, improved productivity, and top-tier package protection with this state-of-the-art packing solution.

Applications of Fully Automatic Strapping Machines

Eagle’s fully automatic strapping machines are widely used across multiple industries due to their versatility and reliability.

Manufacturing Units

Used to strap cartons, bundles, and pallets for internal handling and dispatch.

Warehousing & Logistics

Ensures secure packaging for storage and long-distance transportation.

E-commerce & Retail

Ideal for high-volume packaging where speed and consistency are critical.

Food & Beverage Industry

Provides hygienic and secure strapping for cartons and boxes.

Pharmaceuticals

Ensures tamper-resistant and uniform packaging.

Paper, Textile & Printing Industries

Efficiently straps bundles, reams, and cartons without damaging the products.

Fully Automatic Strapping Machine for Cartons and Pallets

Eagle manufactures fully automatic strapping machines suitable for both carton strapping and pallet strapping applications.

Carton Strapping

Our machines are designed to handle different carton sizes with precision. Automatic sensors detect package dimensions, ensuring accurate strap placement every time.

Pallet Strapping

For heavy-duty applications, Eagle offers machines capable of securing large and heavy pallet loads, providing stability during shipping and storage.

Energy-Efficient and Cost-Effective Packaging Solution

Eagle’s fully automatic strapping machines are designed with energy efficiency in mind. Advanced motors and optimized heating systems reduce power consumption without compromising performance.

This results in:

-

Lower operational costs

-

Reduced energy bills

-

Higher return on investment

For businesses focused on sustainable operations, Eagle’s machines offer the perfect balance between performance and efficiency.

Frequently Asked Questions (FAQs)

Q.1: What is a Fully Automatic Strapping Machine and why should I consider it?

A Fully Automatic Strapping Machine is a packaging equipment designed to automatically wrap and seal strap material around cartons, bundles or pallets without manual intervention in feeding or sealing the strap. Choosing a fully automatic model means higher productivity, consistent strap tension, faster cycle times, and lower operator effort compared to semi-automatic or manual strapping methods. With this machine you can streamline your packaging line, reduce labour input and improve reliability.

Q.2: What are the key specifications of this Fully Automatic Strapping Machine (JN-85UT model)?

The JN-85UT Fully Automatic Strapping Machine features a strap cycle speed of up to about 25 cycles per minute. It supports strap widths from 6 mm to 15 mm, and a tension strength range from approximately 5 kg up to 70 kg (depending on settings). The standard table height is about 810 mm. These specifications give you a clear idea of its capability for mid-to-high volume strapping tasks.

Q.3: How does the strap tension and width capability benefit my packaging process?

In any Fully Automatic Strapping Machine, being able to adjust strap width and tension is crucial for handling different package sizes and weights. With a range of 6–15 mm strap width, this machine accommodates lighter packages and heavier ones without needing separate machines or strap sizes. The ability to tension up to around 70 kg means it can reliably secure large or heavy bundles to prevent shifting during transit. The adjustable tension also helps you avoid over-strapping lighter items.

Q.4: How reliable is this machine and what features support ease of use?

This machine is designed for high reliability: the modular design of the arch, the use of durable components, and the fact that many models in the series are built for continuous operation. It includes features such as auto strap positioning and retry feeding (which means that if the strap feed fails or mis-feeds, the machine detects and corrects) to reduce downtime. The design also emphasises operator safety—low voltage internal control circuits (24 V) are employed in some models. All of this means less operator intervention, fewer stoppages, and smoother integration into a packaging line.

Q.5: What kind of packages is this Fully Automatic Strapping Machine suitable for?

Given the strap width and tension capabilities, this Fully Automatic Strapping Machine is ideal for a wide variety of packages: cartons, bundles, printed materials, plastics or board-wrapped goods, and even pallet loads (depending on optional configurations). The modular arch means it can be adjusted or replaced to accommodate different package heights or widths. If you have frequent changeovers between product types, this flexibility is a big plus.

Q.6: What about integration with conveyors or production lines?

Yes — one of the advantages of a true Fully Automatic Strapping Machine is that it can be integrated with an in-line conveyor system for continuous flow packaging. The documentation for the JN-85 series indicates optional photocells and conveyor interfacing so the machine can automatically detect packages, strap them, and send them on down the line. This means less manual handling and a smoother packaging throughput.

Q.7: How do I choose the right Fully Automatic Strapping Machine for my operation?

When selecting a machine, focus on these key criteria: package size (minimum and maximum), package weight, expected throughput (cycles per minute), budget, and integration requirements (i.e., manual vs in-line). Since this machine supports up to 25 cycles per minute and moderate to heavy tension, it’s well suited for many production environments. If you have very large pallet loads or extremely high throughput, you may need to evaluate the next-level model. Also consider future growth — choosing a fully automatic model today gives you flexibility as your volumes expand.

Q.8: What is the benefit of purchasing from Eagle Manufacturing Company?

By purchasing your Fully Automatic Strapping Machine through Eagle Manufacturing Company, you benefit from specialist packaging machinery knowledge, dedicated after-sales support, spare parts availability, and installation guidance. Ensuring correct installation and training your staff will further enhance the machine’s performance and longevity.